Capabilities

INJECTION MOLDING

Providing custom high and low volume plastic injection molding of intricate shapes to today’s high standards is the core of what Ritz Plastics provides. Meeting our customer requirements efficiently and on time, is what sets Ritz apart from other molders.

OVERMOLDING

INSERT MOLDING

Insert injection molding is the process of molding or forming plastic parts around other, non-plastic parts, or inserts. The inserted component is most commonly a simple object, such as a thread or rod, but in some cases, inserts can be as complex

METAL REPLACEMENTS

- Lower production costs

- Decreased component weight

- Removal of secondary processes (such as e-coat)

- Increased structural integrity of the product with proper design changes

- Lower expenses for packaging and shipping

- Improved manufacturing cycle times

- Predictable and repeatable manufacturing

- Superior flexibility in design.

- Longer product life

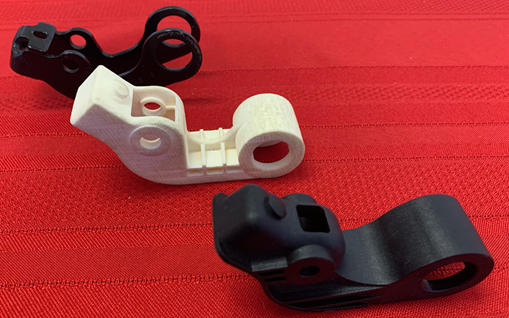

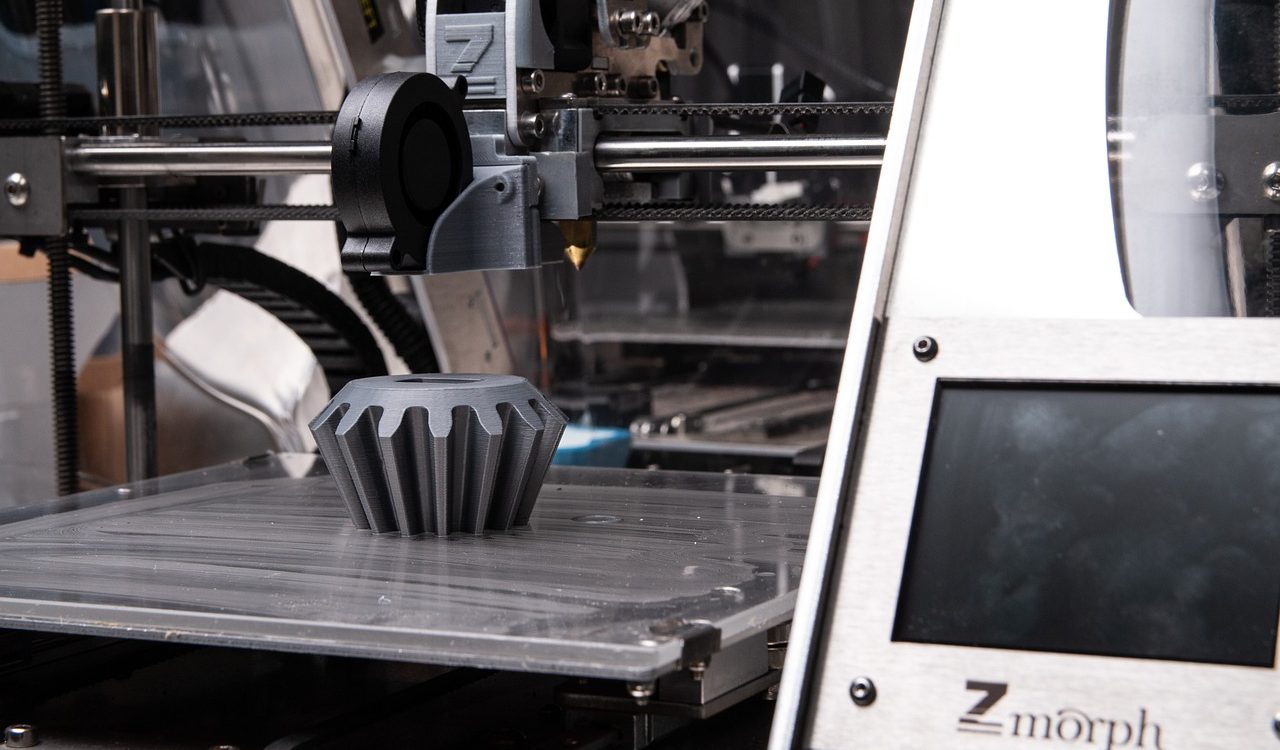

3D PRINTING

Ritz Plastics, working with a core group of suppliers, provides customers with the option of 3D printing their parts. We are able to produce quick models which can be used to change, adjust and improve the product so the customer gets exactly what they are looking for!

Prototype / Low Volume Production Tooling

PRODUCTION TOOLING

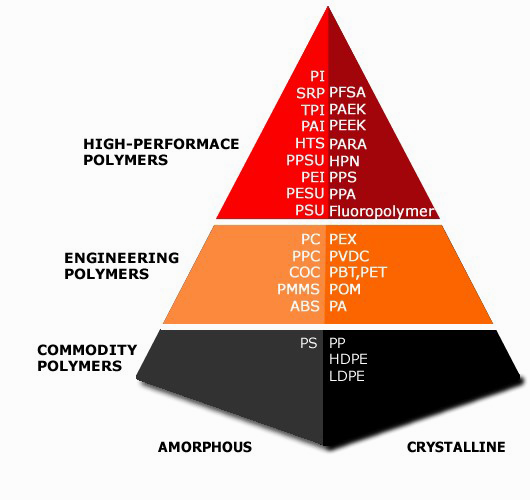

MATERIALS

Ritz relies on customer recommendations for material selections and works with customers based on their design criteria and material selections to provide a plastic injection molded component that will meet their requirements. The various types of materials that we use are:

High Performance polymers are characterized by their superlative mechanical, chemical and thermal properties. Polymer types include Fluoropolymers, high-performance Polyamides, Polyketones and Polyphenylene Sulphide. Demand for high-performance polymers tends to be driven by new product development and innovation; as well as by regulatory controls (for example ATEX).

Engineering polymers have a structure that is random when liquid but becomes organized into crystalline groups when solid. They have a sharp melting point and have excellent mechanical properties such as stiffness and strength. These resins have high performance in tough applications when compared to non-engineering resins.

Commodity polymers generally exhibit lower mechanical properties, but are typically lower in cost compared to engineering polymers. They are used in a wide and diverse range of products, for example polythene bags (polyethylene), vacuum-formed food packaging (low density polyethylene) and disposable drinking cups (high impact polystyrene).